To get the best results and to avoid problems, it's important to choose the right type and size of machine needle for the fabric and project you are sewing.

To a sewing newbie the choice that's now available can be somewhat daunting at first glance. So let's enlighten you by explaining how the different types and sizes are best used. Even the experienced Sewist may find some of this info useful.

As a bonus, reading this post will hopefully give us a chance clear up the "misinformation" that's languishing out there on the old internet; some of which we've found to be totally incorrect.

Also, it will be worth reading up about Twin & Special Effect needles in our previous posting.

SHOP ALL MACHINE NEEDLES »

Domestic Machine Needles

With the exception of the really ancient, all domestic sewing machines now take the same system of needle. These are widely available, and the code on the pack will usually say 130/705 and/or HAX1

Non specialist outlets such as supermarkets, large hobby & craft stores, etc have a somewhat limited choice, so you won't usually find the range that's featured here.

We've split this post into three categories:

Needle Sizes

Where we explain which size of needle is suitable for which weight of fabric: i.e. lightweight, heavy, etc.

Fabric Specific

Where we cover the different types of needle that are available for certain fabrics: i.e stretch, satin, denim, etc

Project Specific

Here we'll talk about needles that have been developed for specific tasks such as quilting and machine embroidery, etc.

Sizes Explained

60,70,75,80,90,100,110??

With machine needles, the lower the number, the finer the needle.

Below, we've listed a general guide to needle versus fabric weight, but this is not an exact science; so you'll need to rely on your own judgement to asses what qualifies as lightweight, medium or heavy weight fabric.

'60' (extra fine)

for very delicate, lightweight fabrics such as georgette, organza, tulle and very lightweight silks and satins.

'70' (fine) for lightweight fabrics

Crêpe de chine, taffeta, cotton lawn, lightweight silks and satins, peachskin, lightweight stretch and jersey.

'80' & '75' (fine to medium)

for poly cotton, cotton poplin, chambray, lighter weight linens, most light or medium weight jerseys.

'90' (medium to heavy)

medium weight cottons, linens, light to medium weight denim, medium weight coating, suiting and drill, medium weight jerseys. Light to medium weight leather, suede, pvc leather look

'100' & '110' (heavy to extra heavy)

heavy weight coating, heavy weight denim, canvas, outdoor fabric, heavy weight leather, suede, pvc leather look, webbing.

Types of Needle - Fabric Specific

Universal / Standard

This is the most commonly used machine needle. Best suited for woven fabrics such as cotton, linen, poly cotton and similar. You can also get by on most satins, silks and other lightweight woven fabrics.

Should this fabric be very densely woven however, then you may find that the needle will pull a run in the fabric. Or puncture the fibres causing the stitching to appear unsightly. To avoid this problem, use a Microtex Needle (see further down).

Universal will also work well on some jersey fabrics such as stretch cotton and certain synthetic stretch fabrics. However, if the stretch fabric is very densely knitted, you may experience skip stitching; in which case, a Stretch Needle should be used. (see further down)

SHOP NOW »

Self Threading Universal / Standard

Take the frustration out of threading your needle!

Simply draw the thread down the side of the needle until you reach the eye and job done!

They're a Universal / Standard point (as above) and are available in size 80 or 90

SHOP NOW »

Ball Point / Jersey

Mainly used for natural jerseys: stretch cottons, wool jersey, Ponte Roma and similar, as well as knitwear, etc. They'll also work well on some synthetic jersey providing it's not too densely knitted. If you experience skip stitching with jersey fabrics, try a Stretch Needle (see below)

SHOP NOW »

Stretch Needle

There are some stretch fabrics on the market which as lovely as they are, will cause your machine to skip stitches every so often.

The Stretch Needle was developed to prevent this problem and will generally do the job.

The main reason for the skip stitching is due to the high Elastane fibre content and the very tightly knitted fabric structure.

This deforms the thread loop that the needle makes after the point and eye have entered the fabric; resulting in the Hook (the part that connects upper and lower threads) missing the needle thread and subsequently preventing the stitch from being formed.

The Stretch Needle has a slightly rounded point, a smaller eye with a very tiny bump at the back which helps to maintain a uniform thread loop. In addition, the flat side of the needle is designed so that it sits just a tiny fraction nearer to the stitch mechanism. This design combination ensures that the Hook picks up the needle thread loop and so prevent skipped stitches … Clever stuff!

SHOP NOW »

Microtex Needle

Developed for very tightly woven fabrics such as silks, satins, peachskin, taffetas, ripstop, etc. and foil coated fabrics such crushed Lamé, paper Lamé.

The specially designed, extra sharp, fine point will pass easily through the fabric layers without deflecting.

The point will also reduce the likelihood of thread pulls and the fibres puncturing as the needle passes through.

In addition, because there is minimal deflection on the needle, a more uniform straight stitch is formed.

SHOP NOW »

Denim / Jeans

As the name suggests, these are designed for sewing jeans and denims. They're also ideal for most other heavy weight woven fabrics.

The protracted taper from the needle eye down to the point will easily pass through multiple layers of thick fabric, reducing deflection and minimalising the risk of breaking.

Use size 90 for the lighter to medium weight denims or size 110 for heavy weight denims.

Size 110 is best when sewing with thick jeans or upholstery thread.

The larger eye on this needle will allow thick threads to pass through freely.

SHOP NOW »

Leather Needle

Does what says on the pack!

Perfect for natural leather or suede, and medium to heavy weight, PVC leather look.

The specially designed, spear shaped point will penetrate the layers with minimal resistance.

The large eye on size 100 will allow thicker threads to pass freely.

SHOP NOW »

Titanium

Particularly good for rubberised fabrics such as Neoprene, and composite materials which may adhere to the needle.

They also help in eliminating problems encountered when embroidering designs that have dense, very tightly packed stitching.

Titanium coating gives added strength to reduce needle deflection as well as the risk of breaking. Titanium needles are ultra smooth; this stops the fabric gripping the needle as it lifts to complete the stitch cycle, preventing thread snagging.

SHOP NOW »

Types of Needle - Purpose Specific

Embroidery (non metallic thread)

See further down for metallic thread

For machine embroidery and particularly good for machine embroidery with specialised threads such as Madeira Rayon, Sulky Rayon, Polysheen, Brother, etc.

Ideal for computerised or freehand.

The specially designed eye will reduce friction on the thread, which in turn, will help to prevent shredding. The point is very slightly rounded which allows the needle to get between existing, embroidered threads that have already been stitched.

SHOP NOW »

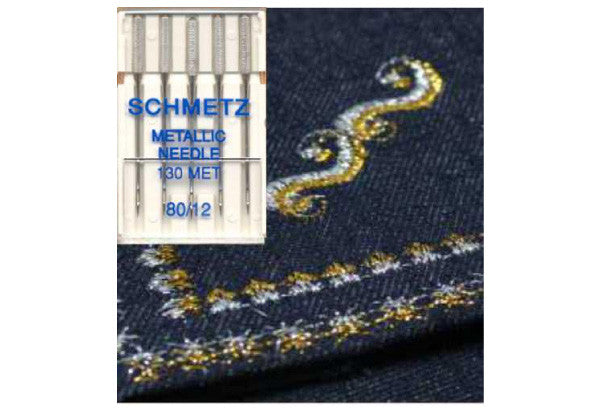

Embroidery (metallic thread)

These are very similar to the non metallic embroidery needle. The main difference is the longer eye in comparison to the non metallic version.

Suitable for freehand or computer machine embroidery and ideal for both core-spun or flat-foil metallic threads.

The longer shape of the eye will greatly reduce friction on the thread as it passes through which helps prevent shredding.

The point is very slightly rounded which allows the needle to get between existing, embroidered thread that have already been stitched.

SHOP NOW »

Quilting

Use when sewing quilt layers.

Helps maintain a uniform straight stitch and prevent skip stitching.

The special taper leading from the eye down the point allows the needle to get through quilt layers and prevent the fibres in the quilt wadding from interfering with the thread as it passes through.

SHOP NOW »

Top Stitch

Topstitch needles are the perfect solution where you need to sew with a thicker than normal thread for profile edge stitching on coats, jackets, suits, pockets, etc.

Designed to work with the heavier threads such as jeans and topstich.

The enlarged eye will accommodate these threads with minimal resistance affording a more uniform straight stitch.

SHOP NOW »

Titanium for Embroidery

We'll talk about these again, because they'll help eliminate some of the problems encountered when machine embroidering; particularly with computerised embroidery.

Embroidery designs that are very highly detailed will produce lots of densely packed stitching so as to achieve the desired effect. This causes the needle to deflect or break as the stitches are being formed. Also, due to needle deflection, gaps will appear between the different colours, shapes or outlines in the design. However, the latter may just be due to poor stabilising / hooping.

Very tightly packed stitching will grip to the needle as it passes between the embroidered threads on the fabric. The fabric will then lift slightly upwards as the needle ascends through the embroidery to complete the stitch cycle, resulting in thread breaking or snagging. Titanium coating on the needle is ultra smooth, reducing this likelihood. Titanium also gives added strength to reduce needle deflection, premature blunting and so preventing the risk of breaking.

SHOP NOW »

Twin and Special Effect Needles

We covered this subject in a previous blog post

SHOP NOW »

SHOP ALL MACHINE NEEDLES »